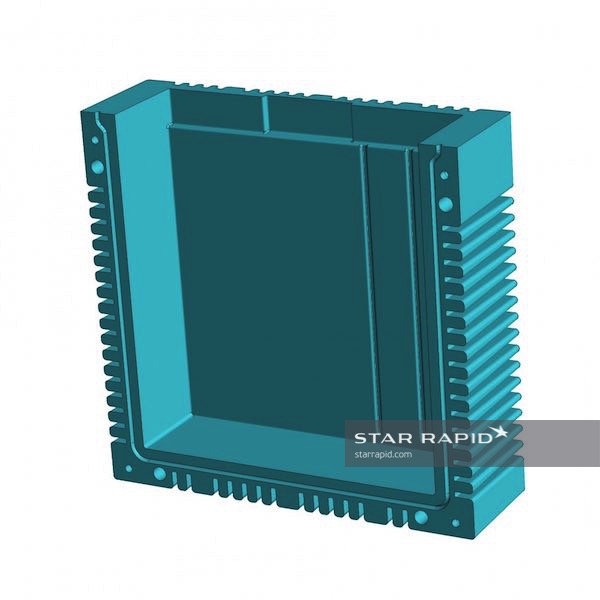

关于产品

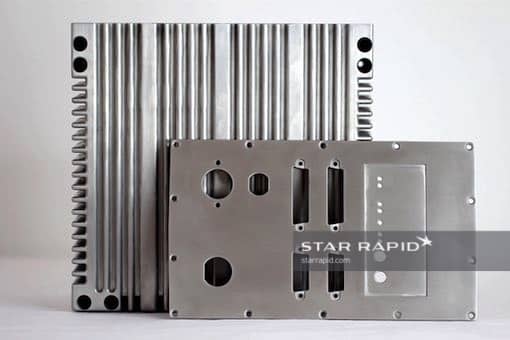

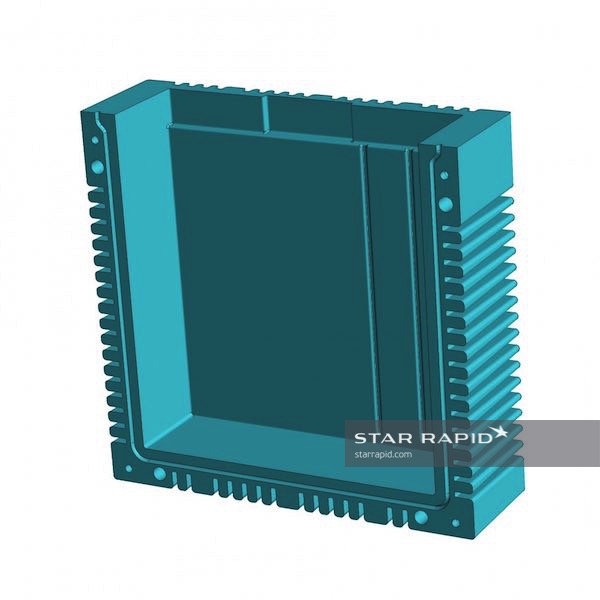

这款产品是铝制的外壳是用于列车无线电通信设备的上盖。因此,必须解除关于产品散热隐患,符合人身安全和预防电器火灾的相关安全规定。产品由两个主体和一个上盖组成。产品内部结构为空心,适合安装各种零部件。

关于客户

我们的客户是瑞士一家定制模拟和数码通讯设备集成系统的公司。之前的项目包括车队安全监控系统,为网络安全提供解决方案和列车无线电通讯设备。

关于项目

对于大批量的铝合金产品生产,压铸是非常理想的加工方式。虽然制造模具的工期相对较长,但是快速、经济的生产高质量的产品。我们的工程师首先会仔细的审核图纸评估项目的可实现性。在审核中发现,我们可以通过对项目的一些内容进行优化来获得期望的结果。

项目挑战

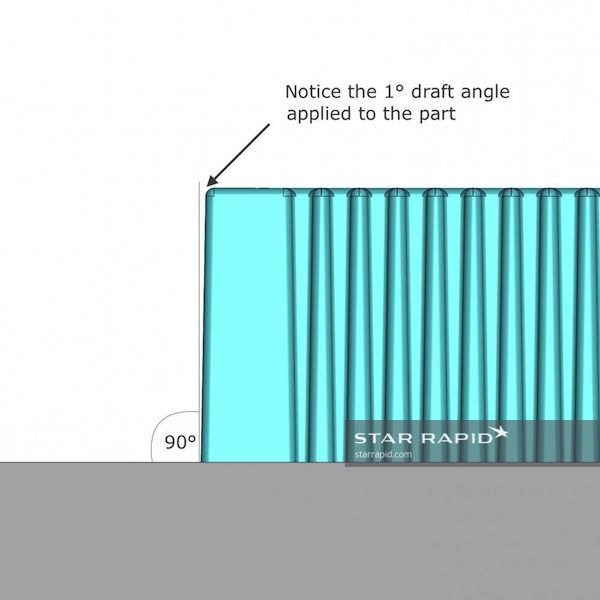

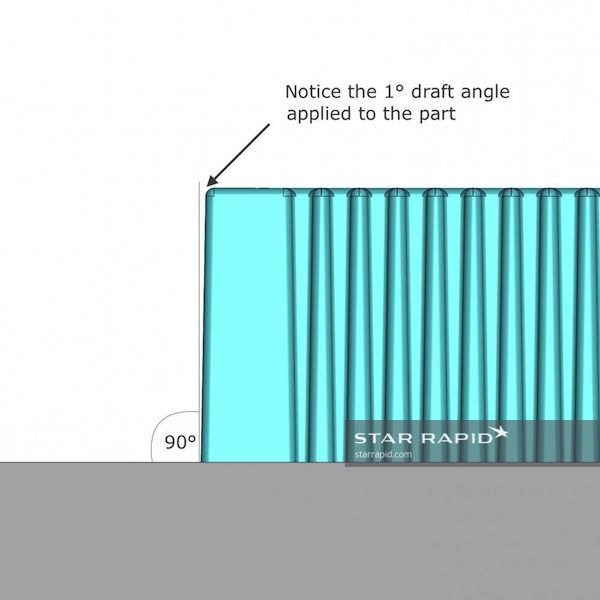

1. 拔模角

拔模角是设计过程中是很关键的环节,而且在最终确定的产品设计中必须要考虑到这一点。如何设计拔模角取决于一系列的因素,包括产品壁厚,特征的深度长度以及压铸材料。

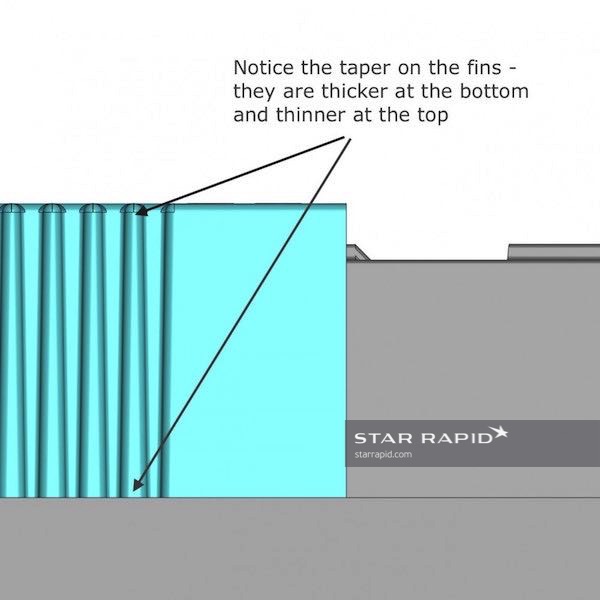

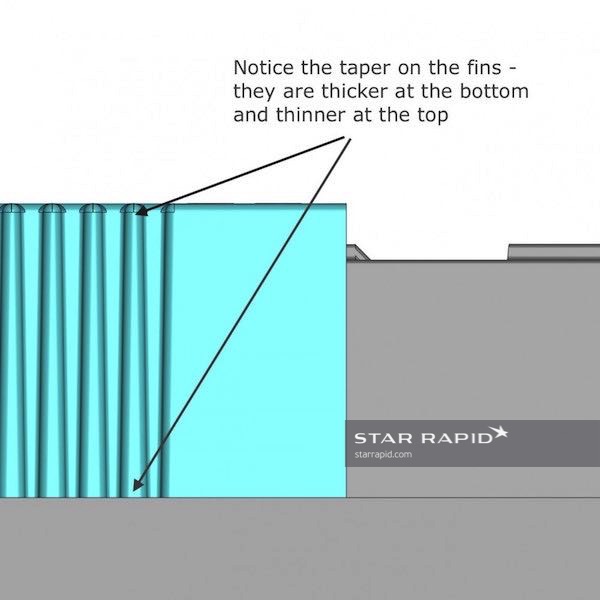

2. 锥度

3. 壁厚

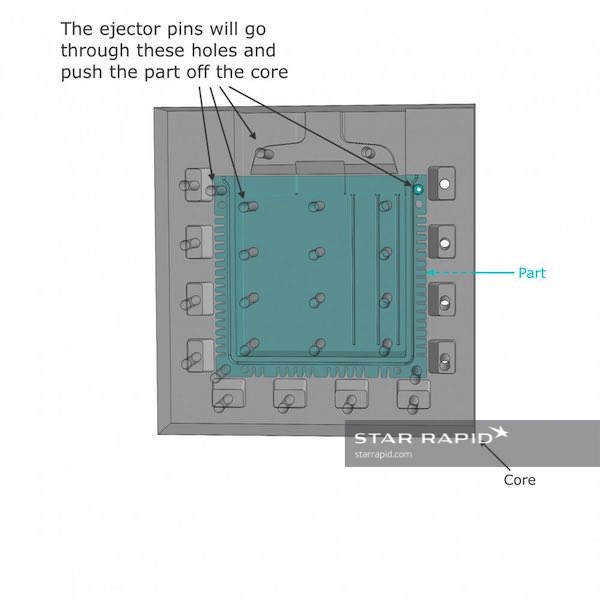

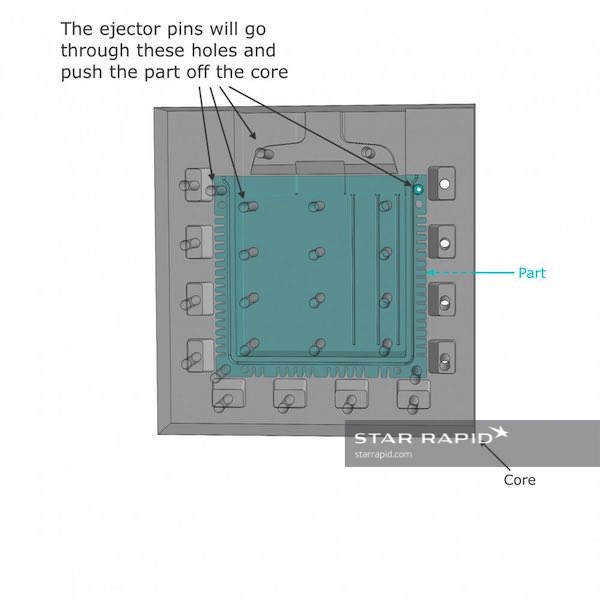

4. 顶针

顶针的作用是将产品顶出模具芯。我们将顶针设置在产品需要钻孔的位置,,这样就可以在后处理的时候去掉顶针的痕迹以保持产品外观无暇。我们还在模芯内设计了一个小的倒扣,可以在模芯内扣住产品令开模更方便。

1. Draft Angles

Like other polyetherimide resins such as PEEK, Ultem is an engineering grade plastic. That means it’s much stronger and more rigid than most thermoforming plastics. It can resist sustained high temperatures and chemical attack, so it’s useful in medical appliances that are routinely steam sterilized. Although it’s possible to plastic injection mold Ultem, we used CNC milling and turning for this project. This is because the customer only needed a few parts and we had to produce them fast while also maintaining tight tolerances.

2. Tapers

Like other polyetherimide resins such as PEEK, Ultem is an engineering grade plastic. That means it’s much stronger and more rigid than most thermoforming plastics. It can resist sustained high temperatures and chemical attack, so it’s useful in medical appliances that are routinely steam sterilized. Although it’s possible to plastic injection mold Ultem, we used CNC milling and turning for this project. This is because the customer only needed a few parts and we had to produce them fast while also maintaining tight tolerances.

3. Wall Thickness

Like other polyetherimide resins such as PEEK, Ultem is an engineering grade plastic. That means it’s much stronger and more rigid than most thermoforming plastics. It can resist sustained high temperatures and chemical attack, so it’s useful in medical appliances that are routinely steam sterilized. Although it’s possible to plastic injection mold Ultem, we used CNC milling and turning for this project. This is because the customer only needed a few parts and we had to produce them fast while also maintaining tight tolerances.

4. Ejector Pins And Undercuts

Like other polyetherimide resins such as PEEK, Ultem is an engineering grade plastic. That means it’s much stronger and more rigid than most thermoforming plastics. It can resist sustained high temperatures and chemical attack, so it’s useful in medical appliances that are routinely steam sterilized. Although it’s possible to plastic injection mold Ultem, we used CNC milling and turning for this project. This is because the customer only needed a few parts and we had to produce them fast while also maintaining tight tolerances.

产品加工过程

制造模具

1.CNC开粗

首先我们会使用CNC数控加工对模腔和模芯进行开粗。开粗的主要目的是在最短的时间内去除多余的材料。我们使用的模具钢没有经过硬化,因此可以非常快速的对其进行加工。在这个步骤没有加工模具内的细节。

2.热处理

在开始加工模腔和模芯的细节前,我们先对模具材料进行硬化处理。模具钢材的热处理是一个复杂的冶金过程,通过设置不同的的温度变化对钢材加热接近熔点,达到表面硬化(在低温下重复加热周期),浸油淬火,最后利用液态氮气低温硬化。硬化后的材料如图中所示表面会有些粗糙,硬化完成之后,我们可以使用火花机加工。

3.EDM加工

散热片之间的槽需要火花机来进行加工。我们根据槽的形状制作了相应的铜工用于火花机加工,这些铜工在生产中会逐渐被消耗。火花机加工可以得到比CNC加工更精密的圆角特征。

4.热处理

在开始加工模腔和模芯的细节前,我们先对模具材料进行硬化处理。模具钢材的热处理是一个复杂的冶金过程,通过设置不同的的温度变化对钢材加热接近熔点,达到表面硬化(在低温下重复加热周期),浸油淬火,最后利用液态氮气低温硬化。硬化后的材料如图中所示表面会有些粗糙,硬化完成之后,我们可以使用火花机加工。

5.精加工

经过开初,EDM和热处理之后,模具会再次搬到数控机床上做最后的加工,通过编程技术和先进的切割刀具,让模具细节之处有精确的公差和更好的表面光洁度。当模具精加工完成后,就会做退火处理

6.退火处理

退火也是热处理的一种,通过受控的加热和冷却循环来使材料变韧并消除热应力。世达模型对所有模具进行了Rockwell 46-48的测试,以确保模具经过多次压铸后的耐久性。

7.模具装配

所有的压铸模具零件加工好之后,我们就会进行装配,包括模芯,模腔和顶销。

1. Rough Machining

First, we roughly machined the cavity and core halves. During rough machining the main purpose is to remove as much material in as little time as possible. The tool steel has not been hardened yet so the cutters can take away material quickly. In this step we are not machining any small details.

2. Heat Treatment (Hardening)

Before we start machining the fine details into the core and cavity, the material must be heat treated. Heat treating of tool steel is a sophisticated metallurgical process using a combination of controlled heating close to the melting point, case hardening (multiple heating cycles at reduced temperatures), quenching in an oil bath, and cryogenic hardening using liquid nitrogen. Afterward, the material looks a bit rough as you can see in the picture. Now that hardening is done we can move on to EDM.

3. Electrical Discharge Machining (EDM)

The depth of the cooling fins within the mold required extensive use of EDM. We custom made EDM electrodes in the exact profile that we wanted to reproduce. Electrodes are “sacrificial” and will be slowly consumed during the course of machining. Also, EDM allows for more precise corner radii than CNC machining.

4. Fine Machining

After rough machining, heat treatment and EDM, we moved the mold to our CNC machining center for the final touches. Complex computer programs and modern cutting tools help to achieve precise tolerances with a high degree of finish. Once the machining was done, the tool steel required annealing.

5. Annealing

Annealing is another heat treatment process, using controlled heating and cooling cycles to toughen the material and remove thermal stress. We tested all of the molds to Rockwell 46-48 to ensure the durability of the mold after repeated die castings.

6. Mold Assembly

We assembled the pieces into a complete die casting mold that included the core, the cavity, and the ejector pins. The mold is now ready to make parts!

压铸加工过程

压铸模具完全加工好之后就会组装到压铸机床上。在巨大的压力下金属材料会倒入模具内腔。这一步要谨慎操作,确保操作人员在倾倒金属时候的人身安全。对于需要大量金属材料压铸的产品,我们通常使用一个自动的浇注筒将金属材料从坩埚倾倒入套筒。同时,安全门可以在压铸的过程中讲操作人员与模具安全隔离

少量的浪费和未使用或溢出的铝合金废料几乎可以百分百回收再利用。

压铸完成之后产品从模具中取出,我们会使用矿物油脱模剂喷洒模具,开始准备重复压铸生产。

这种矿物油不仅在产品脱模时能够提供极好的薄膜保护作用,还可以避免火灾或化学废气对压铸操作者的危害。